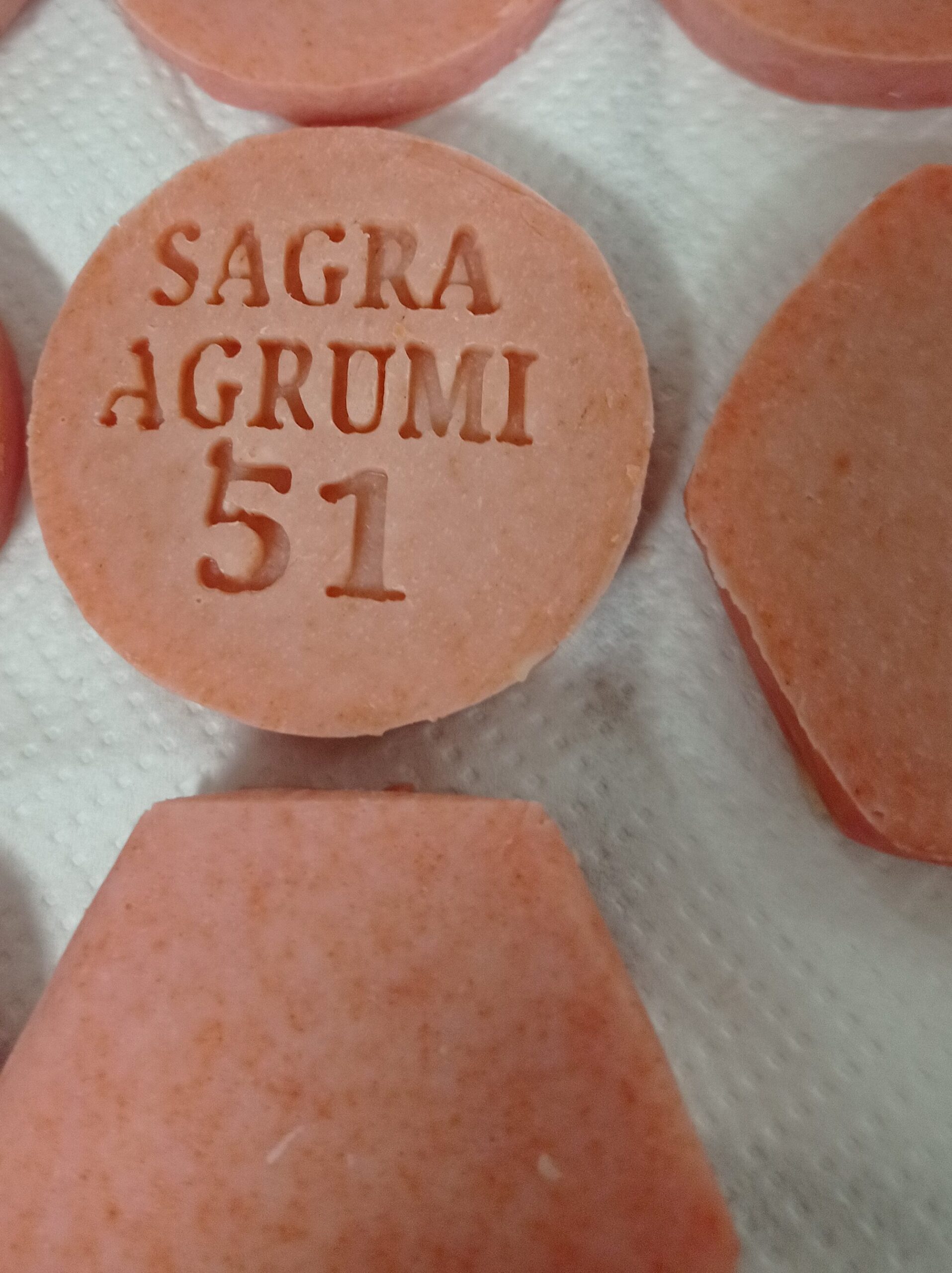

This project was developed in collaboration with a chemistry teacher, as part of an educational initiative for the Sagra degli Agrumi (Citrus Festival) held in Muravera, Sardinia. Our aim was to combine science, technology, and sustainability to create something both useful and meaningful.

We explored how to repurpose orange peels—typically considered waste—by extracting their essential oils to use as a natural fragrance for handmade soap. At the same time, we incorporated informatics and 3D modeling to design and print custom molds. The result? Beautiful, fragrant soaps and citrus-shaped keychains, both created with innovation and care.

Basic laboratory setup for extracting essential oils from orange peels

Extracting Essential Oils from Orange Peels

Orange peels contain valuable essential oils that offer a natural and refreshing fragrance. These oils are known for their antibacterial properties and skin benefits. The extraction process involves steam distillation or cold pressing, methods that ensure the preservation of the citrus scent and beneficial properties. This extracted oil is then incorporated into the soap mixture, enhancing both its fragrance and skin-nourishing qualities.

The soap mixture is poured into a mold while still liquid

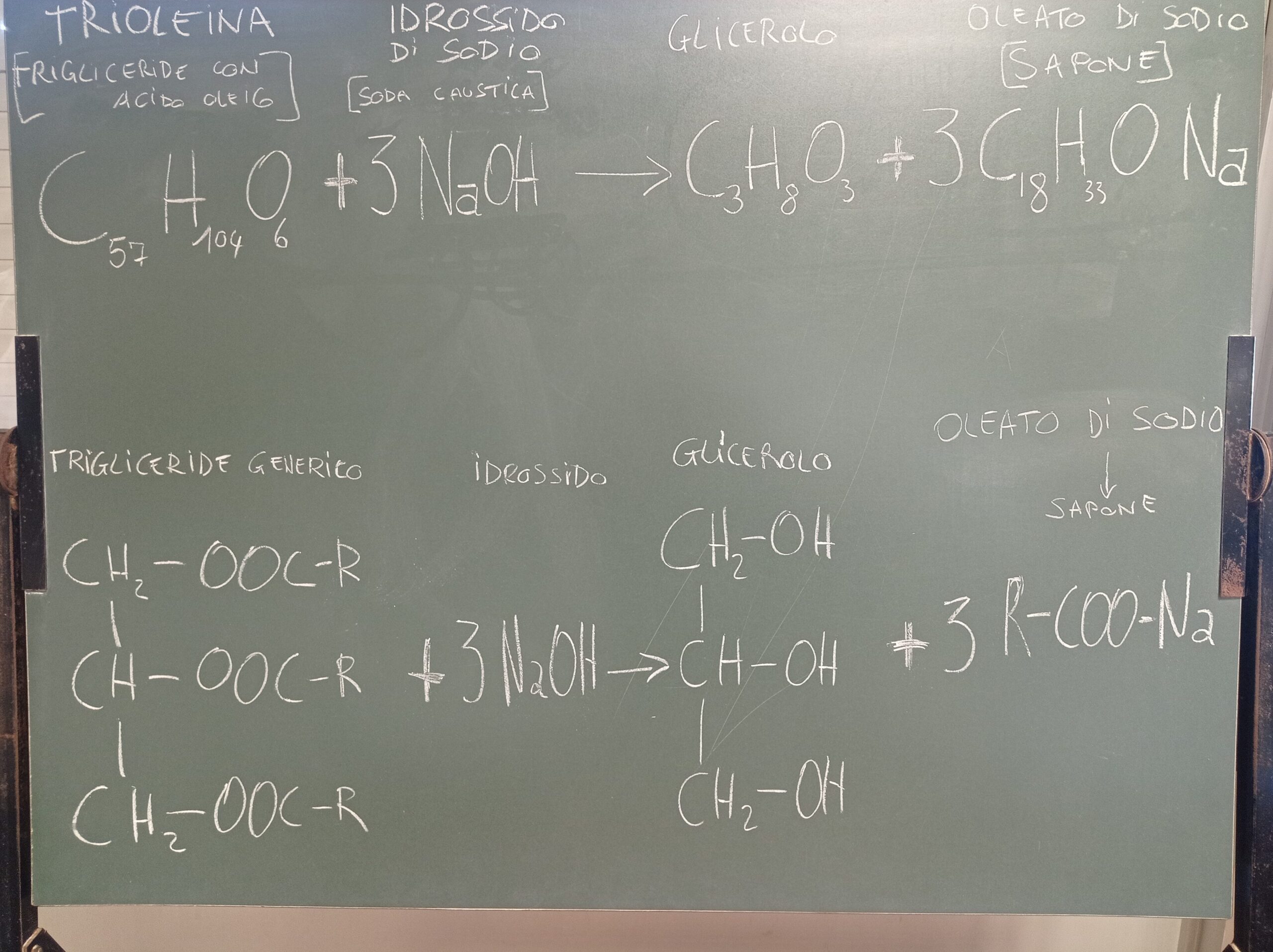

The Chemistry Behind Soap: Saponification

At the heart of the soap-making process is a chemical reaction known as saponification. This reaction occurs when a fat or oil (a triglyceride) reacts with a strong base, typically sodium hydroxide (NaOH), to produce glycerol and soap. The general reaction is:

Fat or Oil (triglyceride) + Sodium Hydroxide → Glycerol + Soap (sodium salt of fatty acid)

Saponification chemical reaction

In our project, we used a vegetable oil base, which reacts with sodium hydroxide to form the solid soap. The orange peel essential oils are added after the saponification process to preserve their aromatic and therapeutic properties.

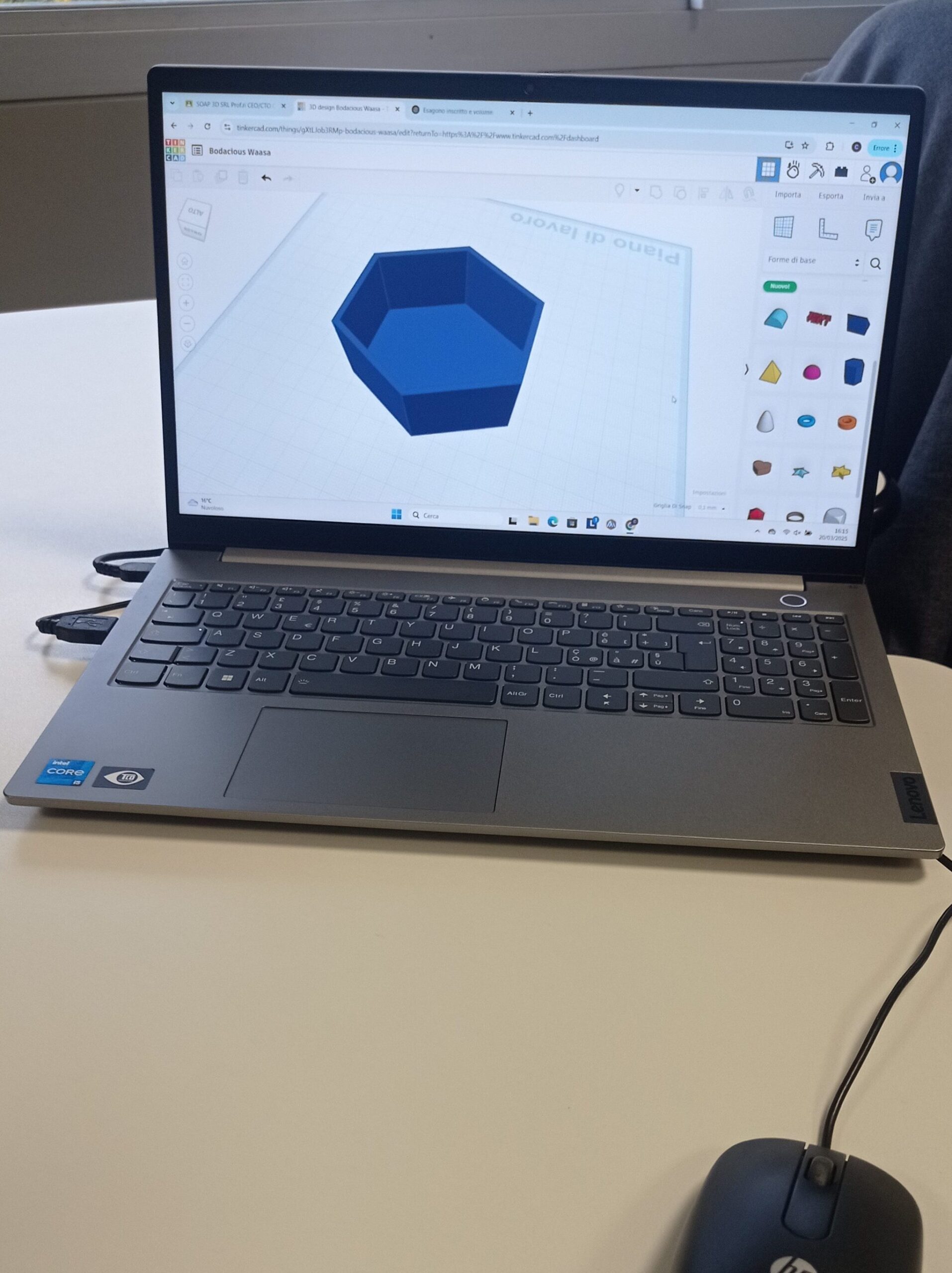

Designing Custom 3D-Printed Molds

Beyond just crafting a high-quality soap, we aim to elevate the visual appeal of each bar. Using 3D modeling software, we design molds that reflect creativity and functionality. These molds are then printed using a 3D printer and filled with the liquid soap mixture. Once solidified, the soap takes on intricate, customized shapes, adding a personal and artistic touch to each piece.

Custom soap mold designed in Tinkercad

3D-Printer in action

Bonus: Orange-Inspired Keychains

In addition to the soap molds, we also designed and 3D-printed small orange-shaped keychains. These colorful and fun accessories served as creative giveaways during the festival, and demonstrated how digital design tools can turn a simple idea into a tangible object. It was a great way to blend chemistry and computer science into a unified, hands-on learning experience.

3D-printed small orange-shaped keychains

Sustainability and Innovation in Soap Making

This project merges sustainability with innovation, proving that upcycling waste materials can result in high-quality products. Not only do we reduce food waste by utilizing orange peels, but we also employ modern technology to make the process more versatile and customizable.

Handmade soap for the citrus festival

Conclusion

By integrating natural ingredients and advanced technology, we demonstrate a creative approach to sustainable living. This project showcases how simple waste materials can be repurposed into valuable and artistic products, encouraging both environmental consciousness and craftsmanship.

This initiative is a step toward a more sustainable and innovative future—where waste is not discarded, but reinvented into something beautiful and functional.